PRODUCTS

Irizar Forge is dedicated to delivering high-quality forging solutions that comply with the highest standards of safety and reliability for onshore and offshore applications. This is why we offer a comprehensive range of standardised and customised forging products designed to meet the specific needs of these industries.

Irizar Forge Standard Forgings

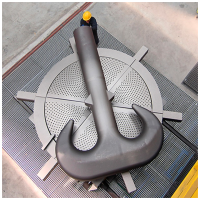

Our standard product line, including crane hooks, hook blocks, shackles and other connectors, combines reliability and efficiency to provide essential and specific components for a wide range of heavy-duty lifting and mooring applications.

Irizar Forge Advanced Solutions

Some projects require more than a standardised crane component. That´s why Irizar Forge offers Irizar Forge advanced solutions: a full-service solution for producing tailor-made forged components in which Irizar Forge takes care of the entire development process. The service package ranges from design and production through to testing and third-party certification. This process usually involves close cooperation between the customer and Irizar Forge´s engineering departments – something Irizar Forge excels at.

Irizar Forge has a proven track record in industries ranging from steel and nuclear to construction and hydro. This has led us to understand the needs of the industries we serve and to provide an excellent customer experience during such a development process.

Contact Irizar Forge

How to contact us:

Irizar Forge

Hiribarren 26, 20210 Lazkao

Spain

T: +34 943 88 09 36

E: [email protected]